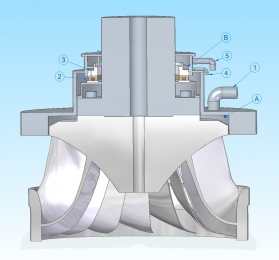

Main Shaft Seal

The purpose of the main shaft seal is to avoid the flow of the water in the chamber A, between turbine upper cover and runner. There are many types of seals depending of some factors. For instance, the turbine dimension and the simplicity to provide the inspection, if the runner is above or under the discharge level, the number of units and the possibility to stop one of them for maintenance etc.

Generally, each manufacturer utilizes his own solution. The figure shows a shaft seal designed for medium and large turbines. This solution was patented many years ago by RIVAHYDROART. Following a brief description of its operation.

The pipe 1 discharge water from the chamber A and consequently the value of pressure decreases. We have to take into consideration that this discharged water influences the hydraulic efficiency because it is a part of the total flow coming from the spiral case, therefor it is useful to install appropriate orifice to control the discharge and the relative pressure inside the chamber A. The seal, indicated with 2, is the main component and it is no metallic material with additional solid lubricant. This component must stand up to the pressure in the chamber A and to the pressure of the water coming from the penstock after to be filtered, injected inside the chamber B by means of pipe 4 and finally inside the seal from the passage 3. The pressure inside the seal allows its lifting in order to permit at the filtered water to flow against the dirty water of the chamber A. The seal lifting avoids also a contact with the underlying plate, increasing the duration of the components. As you know, the value of the pressure in the penstock depends of the available head and consequently the pressure in the chamber A and B. The brief solution above described permits the (theoretical) automatic adaptation following the variables operative conditions. It is useful to highlight that the filtered water flows towards the shaft will be removed through the pipe 5.